Marjan, the master developer of freehold properties in Ras Al-Khaimah, has announced the launch of Mira Coral Bay, a new large-scale waterfront project in the Al-Mairid area. Developed in partnership with Mira Developments, known for its branded property portfolio, this ambitious project is a mixed-use destination that will redefine Al-Mairid’s status as an investment and tourism hub. Mira Coral Bay is a substantial investment in the waterfront residential community, underscoring Marjan’s commitment to enhancing the emirate’s real estate landscape.

Mira Coral Bay comprises multi-use properties developed in collaboration with various reputable lifestyle brands. The partnership with Mira Developments marks a significant milestone for Marjan’s subsidiary, the RAK Dredging Company, which is developing Al-Mairid into a unique destination with world-class infrastructure in line with Ras Al-Khaimah’s vision of emerging as a leading tourism and investment magnet in the region.

“At Marjan, we are committed to developing best-in-class properties that enhance the local topography and provide world-class facilities, befitting Ras Al-Khaimah’s global stature in the real estate market. Mira Coral Bay is a unique offering representing our futuristic vision for the emirate’s evolution as an investment and tourism hub. Al-Mairid is fast transforming into one of the emirate’s most desired destinations, and our partnership with Mira Developments will further boost the local economy while setting new standards in luxury living in the suburbs,” said Abdulla Al-Abdouli, chief executive, Marjan.

“We are honored to be a part of this transformative project,” said Tamara Getigezheva, co-founder of Mira Group. “Our vision for Mira Coral Bay is to create a waterfront master development that exemplifies luxury and sophistication, offering residents and visitors an exceptional lifestyle experience rooted in the DNA of world-leading brands.”

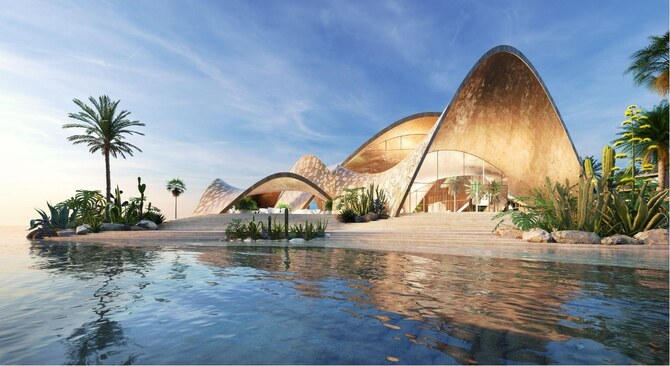

With a masterplan by Marco Casamonti and Partners/ Archea Associati, a studio with over 200 architectural works worldwide, including the Antinori Winery in Italy and the Li Ling World Ceramic Art City in China, Mira Coral Bay is poised to turn into a landmark destination in Ras Al-Khaimah, attracting discerning investors, residents, and tourists from around the globe.

Each property in Mira Coral Bay, developed in collaboration with world-leading lifestyle brands, will ensure the highest standards of luxury, design, and service. Located just 10 minutes from Downtown Ras Al-Khaimah, Mira Coral Bay will offer residents and visitors unparalleled access to the emirate’s vibrant city life while providing a serene waterfront retreat.

Mira Coral Bay features a five-star branded spa hotel with 100 keys, a resort hotel featuring 250 rooms, a state-of-the-art yacht club, and two exclusive branded beach clubs. A grand jewel in the Al-Mairid area, Mira Coral Bay will also have six clusters of villas comprising 165 units, two clusters of townhouses with 128 units, four clusters of apartments totaling 650 units, and 10 premium branded restaurants. The mixed-use development will include underground parking and scenic walkways with a unique architecture that incorporates the environment and outdoor facilities while keeping in mind the comfort of pedestrians. The master plan is a homage to Al-Mairid’s unique landscape, featuring a serene waterfront set against towering majestic mountains.

Aligned with RAK Vision 2030, Mira Coral Bay is designed to reinvigorate the local economy and boost the emirate’s business and tourism development prospects. The ambitious project marks the beginning of a new chapter for Marjan as the one-of-a-kind infrastructure and architecture positions Al-Mairid as a futuristic residential and leisure destination that will unlock job opportunities and redefine the luxury lifestyle in Ras Al-Khaimah.