KARACHI: Haroon Khan threw a matchstick into his eight ft. hut-style charcoal kiln in Gharo, a small city east of Karachi in Pakistan’s southeastern province of Sindh, that is famous for its windmills and kilns.

His men had already neatly stacked wood inside the kiln, and for two hours, Khan let the smoke from the burning wood escape through its chimney. Finally, he covered it up completely to deprive it of almost all oxygen, so the wood inside would roast gently in its own smoke.

Khan, who like most kiln’ owners belongs to the hilly Dir valley of northern Pakistan, has been in the business for years.

A worker, Noor Khan, waters down the temperature of a kiln at Gharo, a small Pakistani city in southeastern Sindh province on Sept 15, 2019.

“After opening the kiln, the wood is watered for evacuation but still it’s hot,” Khan told Arab News (AN Photo by SA Babar)

“One must be the master of this art, otherwise he will turn the wood to ashes,” Khan said, with a hint of a smile.

For three full days, the wood will smoke itself down to a lightweight black carbon residue, charcoal, the most important element of all popular Pakistani barbecues.

This charcoal kiln in Gharo, a small city some 67 km east of Pakistan’s Karachi metropolis, and famous for its windmills, is set to be filled with wood. Sept 15, 2019 (AN Photo by SA Babar)

When its ready, the charcoal will be watered down before it is packed up for transport to Pakistan’s southern megacity of Karachi, famed for its good food.

“Once we set a fire, we wait for around three to four days and closely monitor the temperature of the kiln after short intervals, to ensure the charcoal is neither burnt nor left too hard,” Khan, who runs a small ‘factory’ of over a dozen kilns, told Arab News.

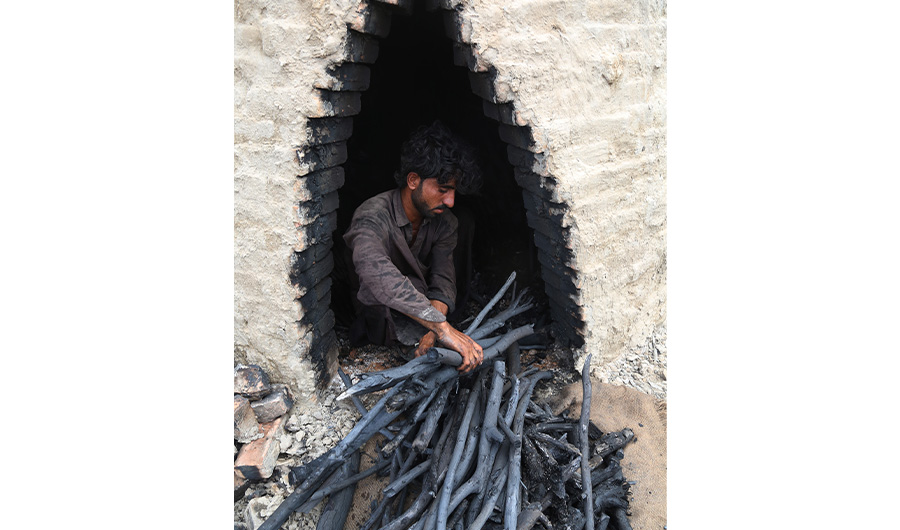

Noor Khan removes charcoal from a kiln in Gharo, a small Pakistani city in Sindh, on Sept 15, 2019. (AN Photo by SA Babar)

Malik Omar Khan, another kiln owner, said the primary raw material, wood, is delivered by dealers and procured at Rs. 150 per 50 kg, with 200 kg of wood producing 50 kg of charcoal.

Charcoal is packed up in large plastic bags, ready to be transported from this small charcoal manufacturing facility in Gharo to Pakistan’s commercial capital of Karachi, some 67 km west of here, for delivery to the city’s restaurants. Sept 12, 2019 (AN Photo by SA Babar)

There are hundreds of these small factories dotted around Gharo, with each comprising 5-6 kilns, and where thousands from northern Pakistan work.

“But it’s not a huge business,” Malik said, and added, “The hard work of a month can barely feed a family.”

Burning charcoal requires no water, and gives off little smoke as compared to regular wood, but is often blamed for deforestation by environmentalists.

Bihari kabab and chicken tikka, both Pakistani barbeque specialties, cooked over the scorching fire of charcoal at Delhi Chicken, a popular barbecue restaurant in downtown Karachi, on Sept 12, 2019 (AN Photo by SA Babar)

Those in the food business, however, argue there is no substitute for it.

“Without charcoal, there is no barbecue and without barbecue... there is no taste to life,” Muhammad Shakeel, owner of Delhi Chicken at Karachi’s downtown told Arab News. He buys a kg of charcoal at Rs. 60.

A worker sorts wood for a charcoal kiln at Gharo city, some 67 km east of Karachi on Sept 15, 2019. (AN Photo by SA Babar)

At Gharo, Khan says he sells one kg for Rs. 40 and the rest goes to dealers who collect it from Gharo and transport it to Karachi for sale at restaurants.

“Karachi is a sea of people. There are a hundred [kilns] here, but (even) if you double the number, the demand will not decrease,” Khan said.